High Precision Cnc Milling Cutter / 0.5UM Grain Size 4 mm End Mill Cutting Tools

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Description:

<table border="1" cellpadding=

Description:

| Details | |

| Product Name | Solid carbide end mills ,Square end miill |

| Production way | Germany CNC grinding+ Swiss Coating |

| Size | Dia:1mm to 25mm AOL:50-300mm |

| Coating | PVD TIALN, ALTIN, TISIN, BALINIT@ ALCRONA PRO |

| MOQ | 50 pcs/size within 12mm |

| Advantage | Not easy fade, environmental , good hand feeling,gorgeous visual |

| TradeInfo | |

| Payment Terms | Paypal, T/T, Escrow, West Union, MoneyGram |

| Lead Time | 3-5 days for sample , 5-7 days for order |

| Shipping | UPS/DHL/FedEx/EMS |

| Delivery Time | Generally 3-7 days |

| Package | OPP bags inside, parcel or export carton outside According to your orders |

| Free Custom Design | Offering one-to-one custom design service without extra fees |

| German Walter | 2 | Tungsten Steel Drill,Endmill,Reamer,Thread Mill | Engineer: 2 Poduction staff: 6 |

20000PCS |

| Australia ANCA | 2 | Tungsten Steel Drill,Endmill,Reamer,Thread Mill | Engineer: 2 Poduction staff: 4 |

20000PCS |

| Miachel Deckel | 2 | Tungsten Steel Endmill,Reamer | Engineer: 2 Poduction staff: 4 |

20000PCS |

Quick Detail:

0.5-0.6um Ultra-Fine grain size solid carbide end mill

TIALN Coating (Purple),SiN(Copper), AlTiN ( Black)

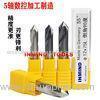

Made by 5 AXIS CNC grinder

Checked by Zoller Inspection Equipment

Workpiece upto HRC55

1 piece packing.

Standard Length Type

Carbide Rod:Wc:88%,Co:12%,TRS:4000N/mm2, Grain Size:0.5-0.6um

***Warm tips for long Shank end mill**

In order to have a good cutting surface and extend the cutting tools life, a tool holder with high precision, high rigidity and good dynamic balance is required.

1. Measure the runout of the cutting tools before using, and if the runout is more than 0.01mm, please readjust it first.

2. The shorter of the length of the stick-out cutting tools is, the better the effect is. If the stick out part is too long, please readjust the rotate speed, feeding speed and cutting output.

3. When hearing unusual sound during the cutting process, please slow down the principle axis' rotate speed and the cutting output until the unusual sound is disappeared.

4. Cooling the steel in a spraying way can maximize the TiALN's effect. Water-soluble cutting fluid is not suitable for stainless steel, titanium alloy and heat resisting alloy.

5. Cutting method is selected according the type of the workpiece and machine. The above information is provided for informational purpose only.

Applications:

Fit for milling quenching and tempered steel.stainless steel.nickel alloy and Titanium alloy,Cast iron,enhanced composited material with fiberglass,Also fit for milling copper.

Specifications:

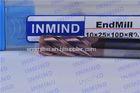

| Order No) | Cutting | Cutting Length | Shank | AOL |

| d | l | D | L | |

| 3.0×8×3D×75L×4T | 3 | 8 | 3 | 75 |

| 3.0×8×3D×100L×4T | 3 | 8 | 3 | 100 |

| 4.0×11×4D×75L×4T | 4 | 11 | 4 | 75 |

| 4.0×11×4D×100L×4T | 4 | 11 | 4 | 100 |

| 6.0×16×6D×75L×4T | 6 | 16 | 6 | 75 |

| 6.0×16×6D×100L×4T |

Related SearchFind more related products in following catalogs on Hisupplier.com

Company InfoINMINDTOOLSCOPANY [China (Mainland)]

Business Type:Manufacturer You May Like:

Printable Page

Bookmark this page

Sitemap XML About HiSupplier Help Center Customer Service Friend Links Site Map Archives Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español Copyright © HiSupplier.com Online Inc. All Rights Reserved.

|